Manganese sand media:It’s became into sand by grinding,removing impurity,drying,magnetic separation, dust removal, screening,etc.It has coarse appearance,shows brown or gray. It can be used in equipment for removal of iron and manganese in drinking water and ground water. The form of manganese is manganese oxide as main.

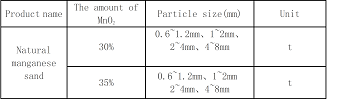

Use of manganese sand: It’s used to reduce the amount of iron and mangane in water. There is a layer of active membrane on the surface which has strong oxidation. In addition,manganese sand can catalyze the two valence iron in the water into a ferric iron and make a ferric iron adsorbed on the manganese sand surface on the purpose of removing iron. (Note: If MnO2≥35%, iron and even manganese can be removed. If MnO2≤30%,only iron in underground water can be removed.) According to the drinking water sanitary standard of China, if the amount of iron is less than 0.3㎎/L and the amount of manganese is less than 0.1㎎/L in water,it must be treated. If you drink water with high iron and manganese,it will affect your health seriously.

This product uses natural manganese ore as raw material and is made by mechanical crushing, drying magnetic separation and dust screening. The appearance is coarse and has more edges. It’s brown. It takes the advantages of grain density, high hardness, corrosion resistance, low loss and long service life. If it’s immersed in water,it is not dissolved and the amount of manganese is not increased. The removal performance of iron and manganese is very good. It’s essential for removal of iron and manganese in industrial water.

Detailed index of manganese sand: