1.Principle of operation

Oxide Mn2+ and Fe2+ in water to Fe3+ and MnO2 by the oxygen in the air.On the basis of removing iron and manganese by aeration, manganese sand catalysis, adsorption and filtration,Mn2+ and Fe2+ in water are oxided to Fe3+ and MnO2 by the oxygen in the air. By using catalysis,adsorption and filter of natural manganese sand, the iron and manganese ion can be removed in water. Oxidation reaction of iron and manganese is as follows:

Iron oxidation:

4Fe2+ +3O2 +6H2O=4Fe(OH)3

Manganese oxidation:

Mn2++ O2= MnO2

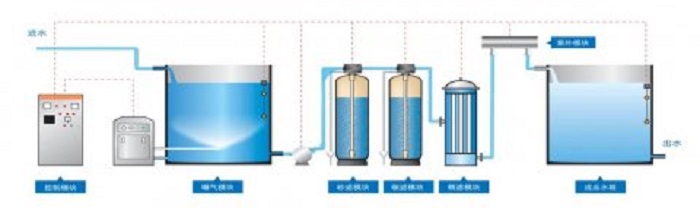

2.Process flow

3.Oxygen enrichment system

Raw water is sent into oxygen water tank through by borehole pump. We set up low noise blower aeration and make water dissolve high dissolved oxygen. Oxide Mn2+ and Fe2+ in water to Fe3+ and MnO2 by the oxygen in the air.

It takes natural manganese sand as the medium whose capacity of manganese is more than 30%~45%. Natural manganese sand use natural sand as raw material and is made by washing and screening process. It has coarse appearance,looks like a ball,is brown and has MnO2 in it. It is a good catalyst for Fe2+ oxidation to Fe3+. By using the adsorption of manganese sand, it can be removed in the filter tube.

We choose 5 micron PP filter which takes the advantages of small volume,large flow,large amount of pollutant,high accuracy, easy operation,etc. It can remove the impurity,precipitation and suspended matter in water and filter leaked trace impurities. It plays a role of security of the whole water supply system and makes the effluent quality meets the drinking standards.